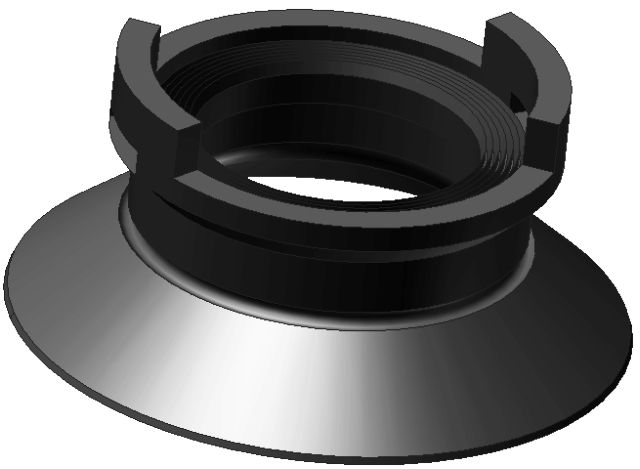

Brake System Components

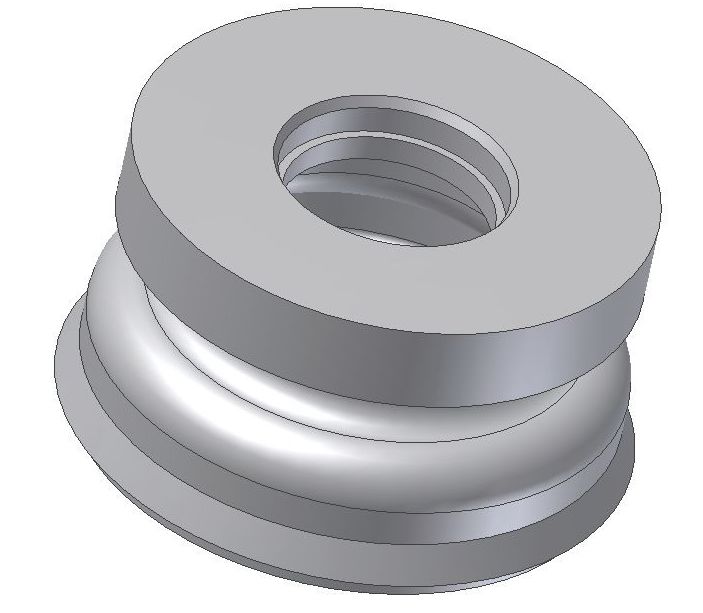

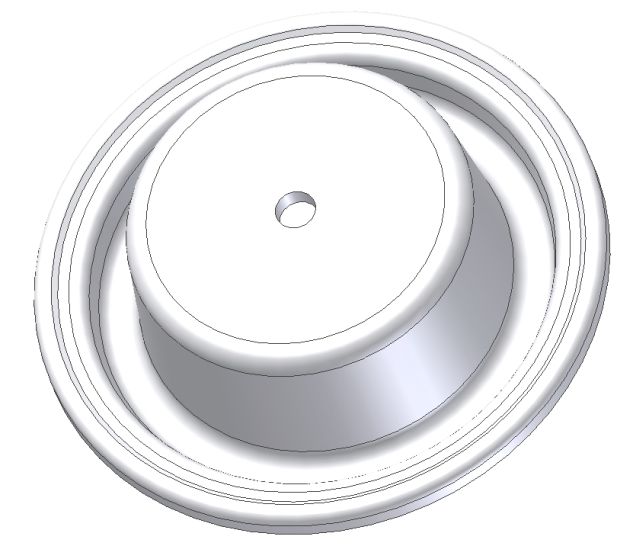

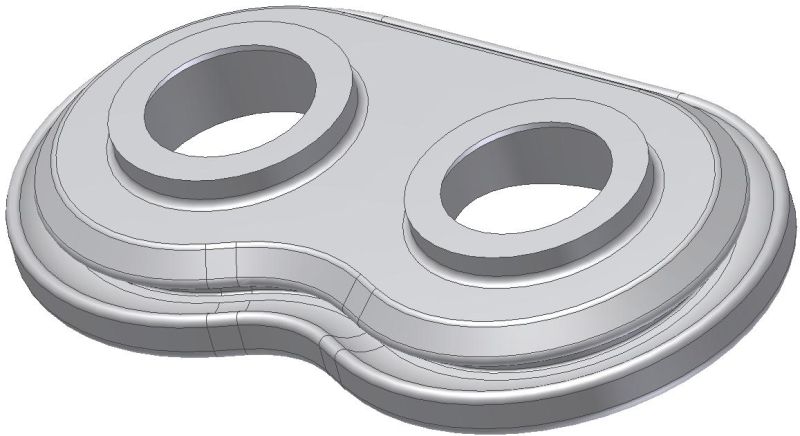

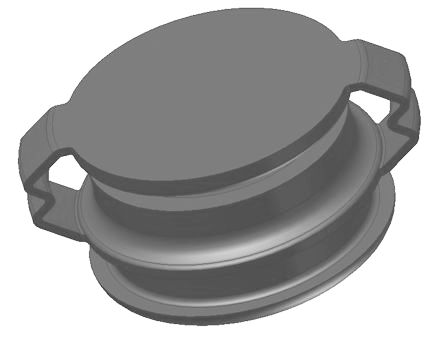

We produce membranes used in brake boosters that are made from a highly resistant material with specific properties that allow it to meet the most demanding application requirements. Along with these brake booster membranes we also supply other rubber brake system components.

.jpg)

SBR or EPDM is used for the membranes as they are resistant to brake fluid. The material is testing in a specific manner to ensure that its meets specific requirements. The material is tested by both our suppliers and in our internal laboratory.

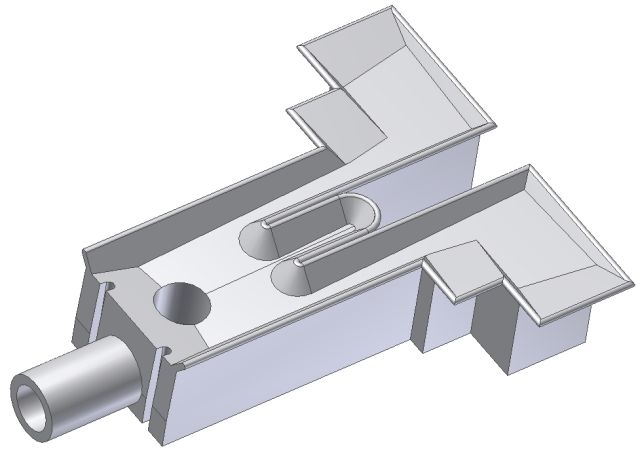

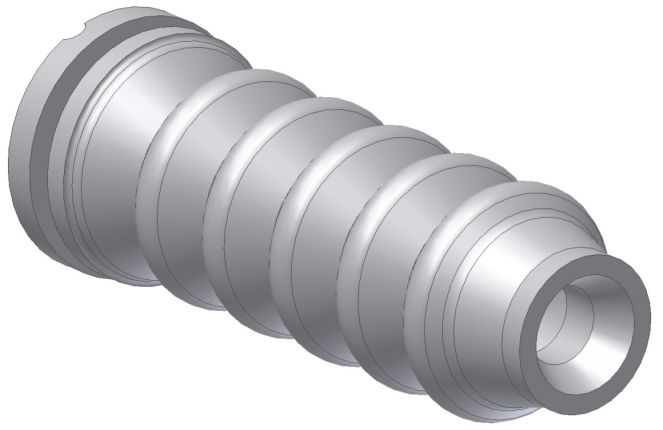

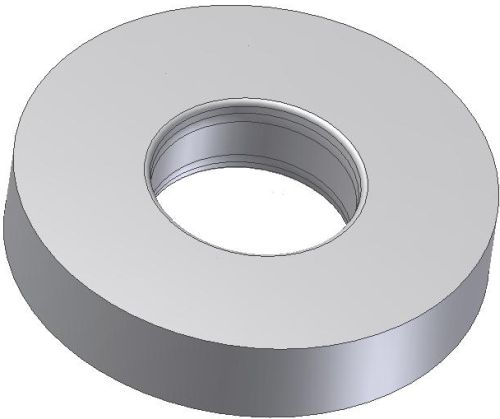

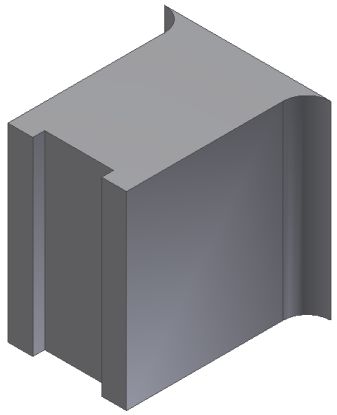

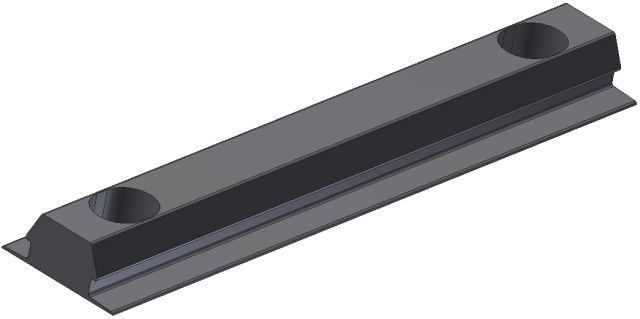

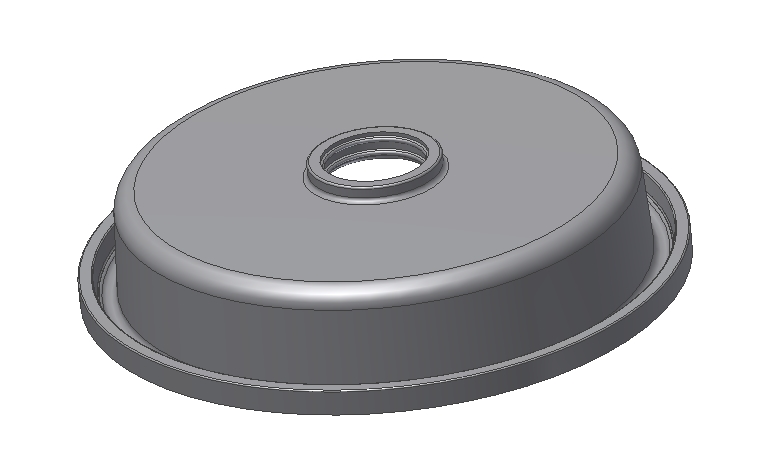

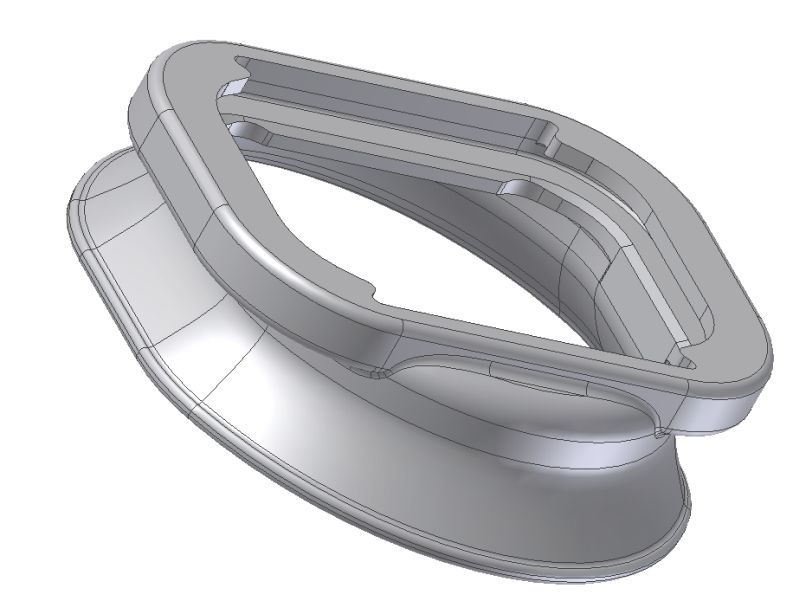

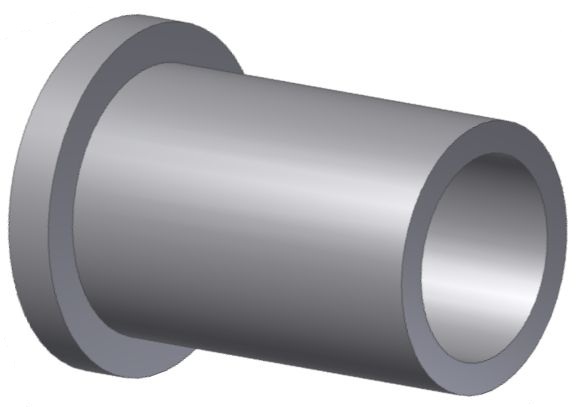

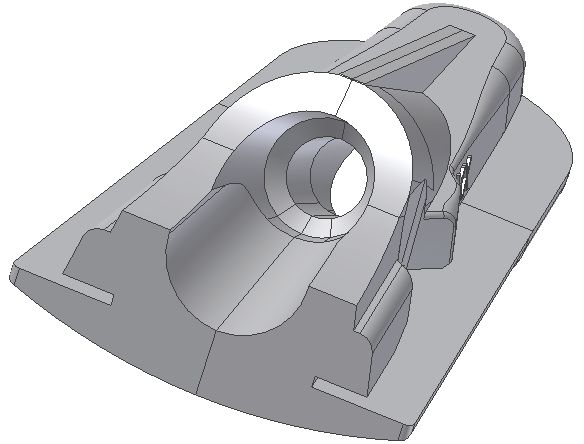

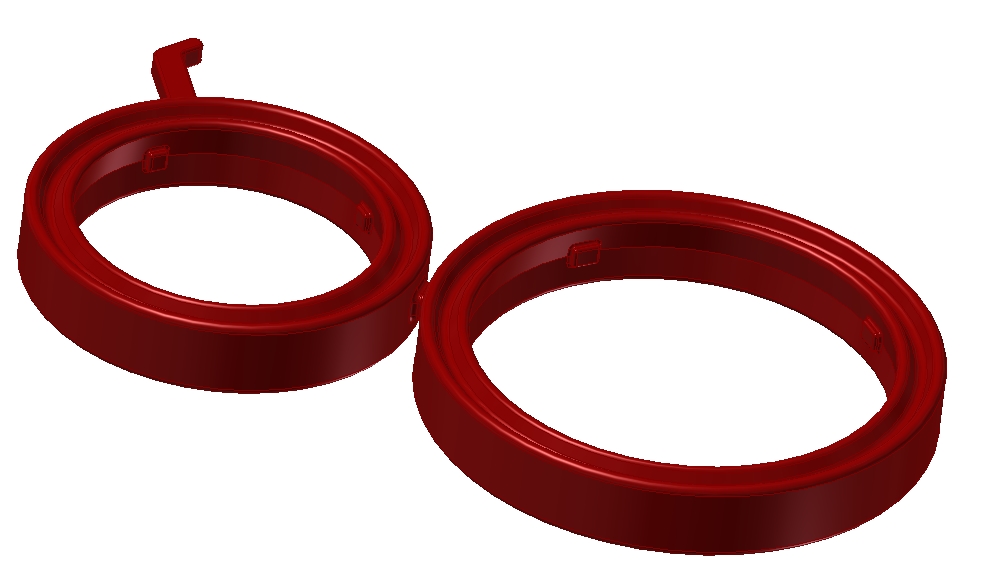

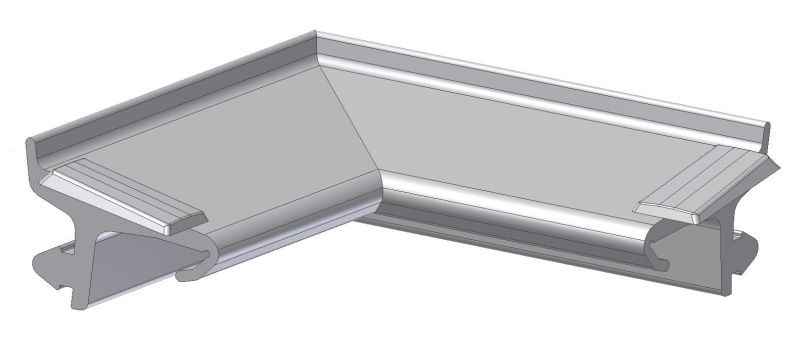

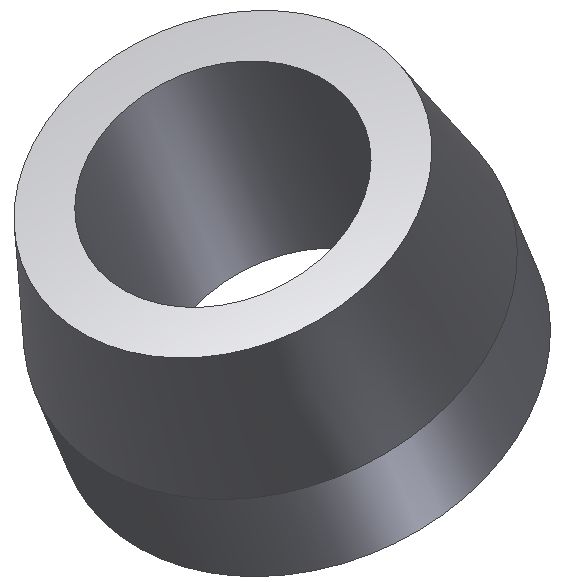

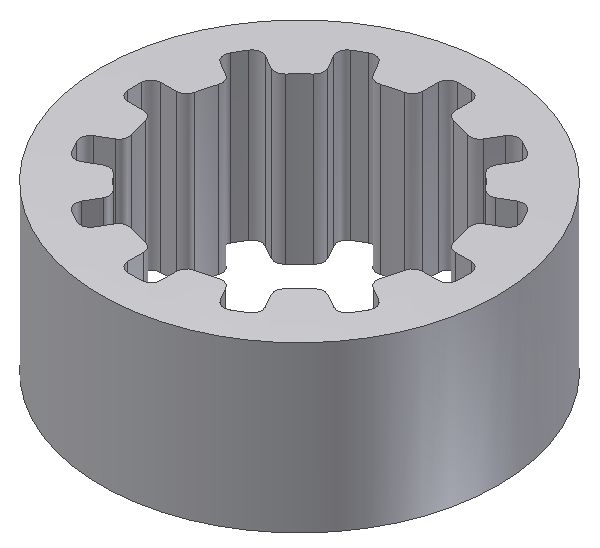

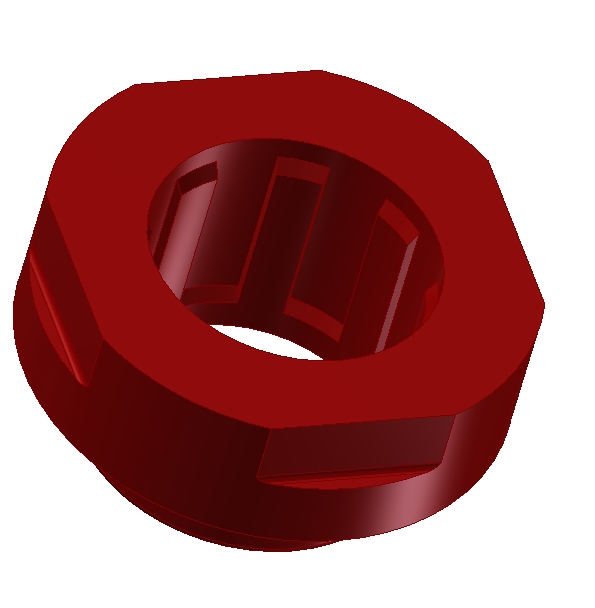

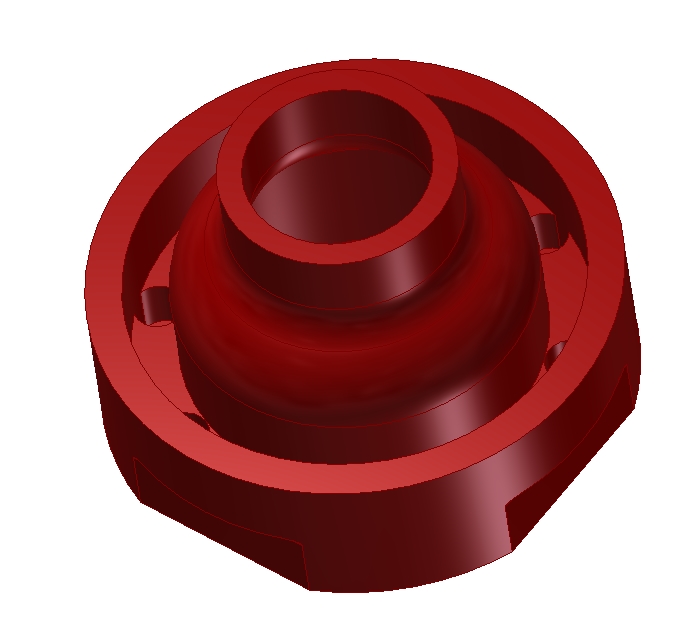

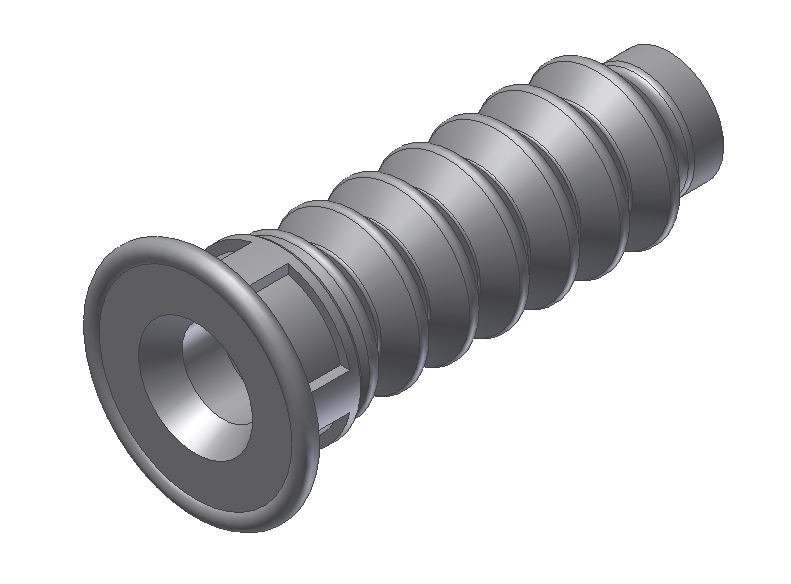

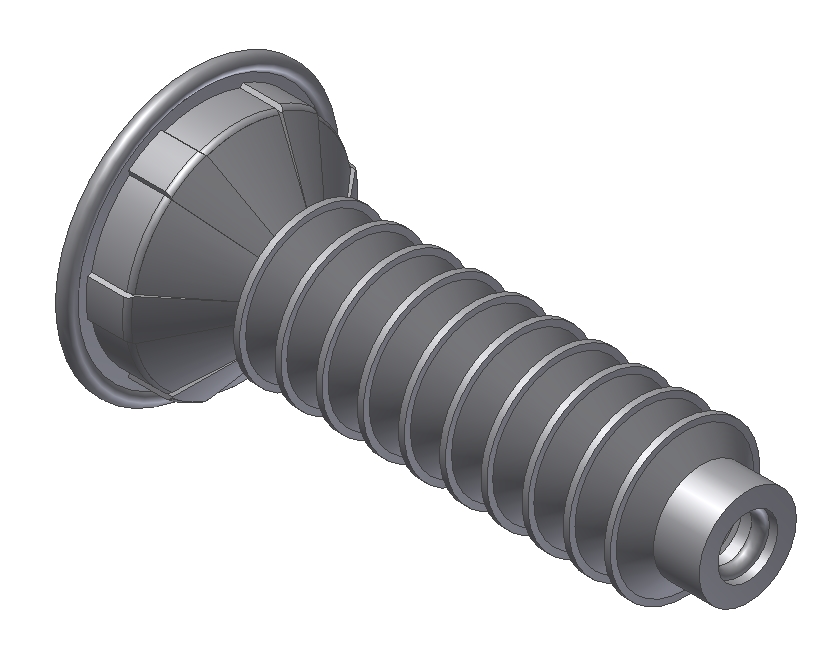

Brake Cylinder

The rubber components that we produce for use in brake cylinders and in seals must also be able to withstand the high demands of the brake fluid environment specific to the given application. These components must be produced to a high level of precision so that dimensions do not cause any loss of seal or reduction in braking performance.

These demands mean that the product dimensions must be very precise and the material itself must be very high quality.

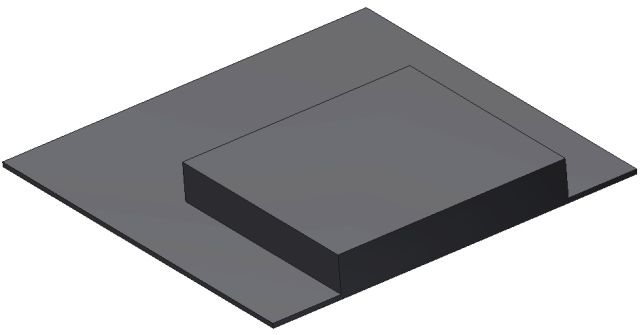

Bumpers are produced for a wide spectrum of customer, most however at intended for the automobile industry. Their uses are defined by specifics of the given application and are used to absorb impacts, such as when opening a window in a car.

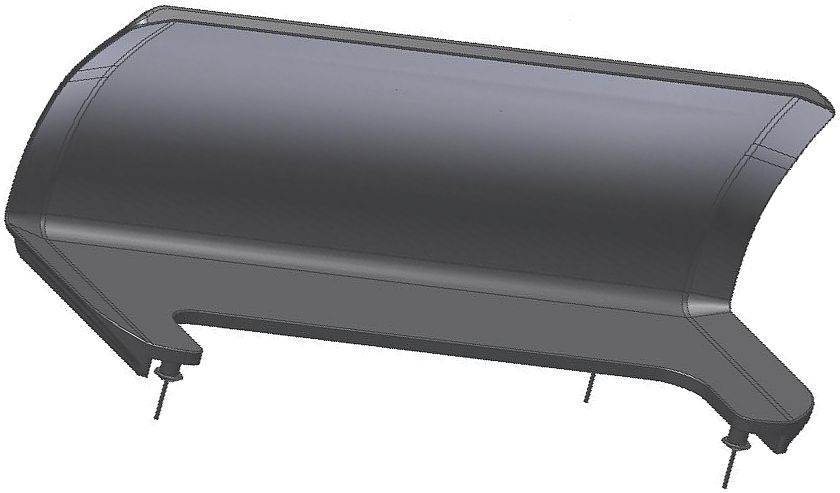

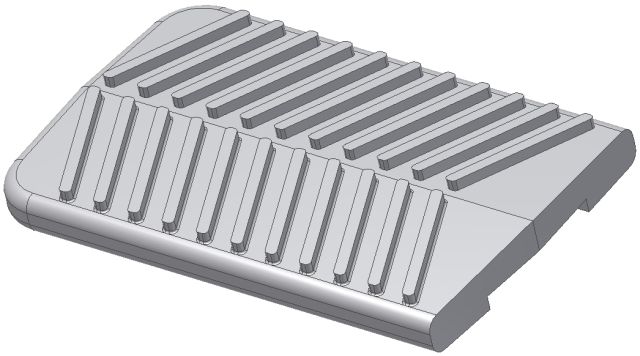

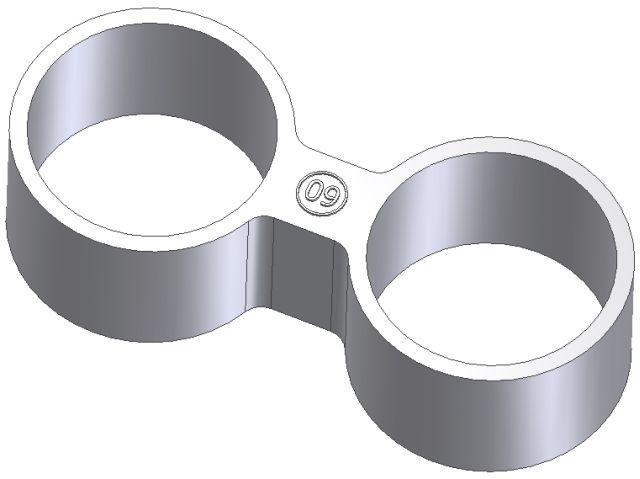

These components are used in cars to cover various bushings, chambers and even to cover pedals. These products can be produced from a range of different types of mixtures. Their shapes are also very diverse. A few are provided as examples.

.jpg)

These components are primarily produced from a highly elastic material. Various types of materials with this property can be used but a VMQ (silicon) mixture is most common. This material is highly elastic and has production properties that make it a great choice for use in these components. A few products from our portfolio are provided as examples.

Membranes have thin walls for the most part and are susceptible to damage such as holes. Such damage may result in a loss of the seal provided by the membrane and the equipment in which membranes are used may no longer be capable of meeting its intended function. We've developed an internal pressure tester capable of detecting the smallest of surface holes in order to ensure the highest level of testing and performance.

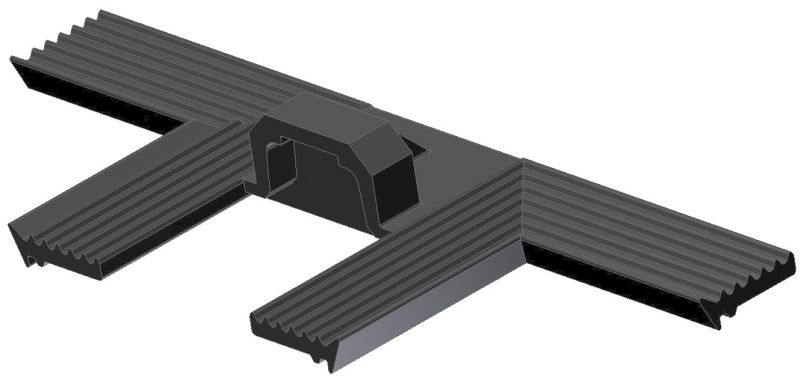

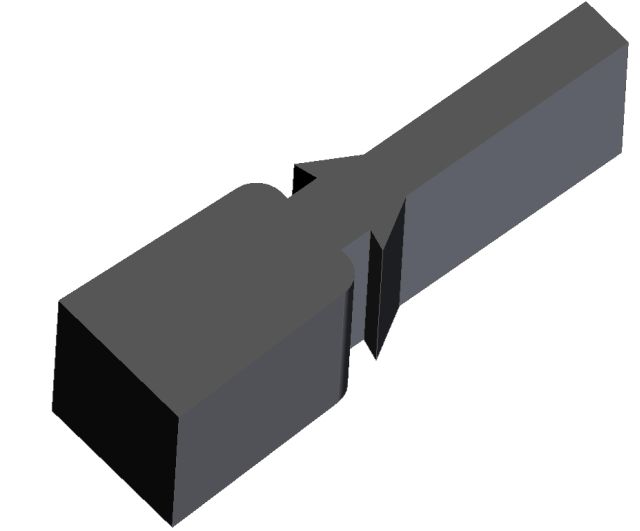

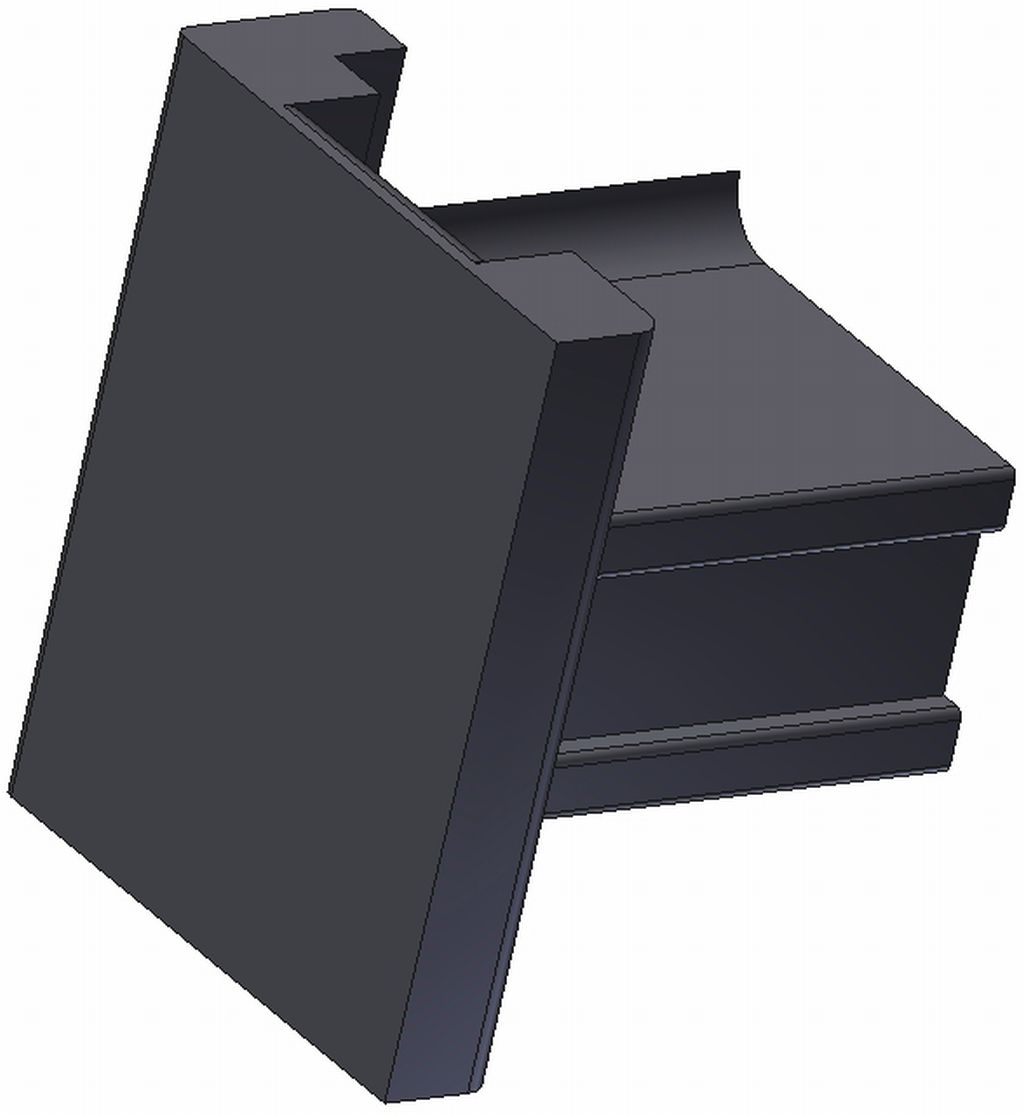

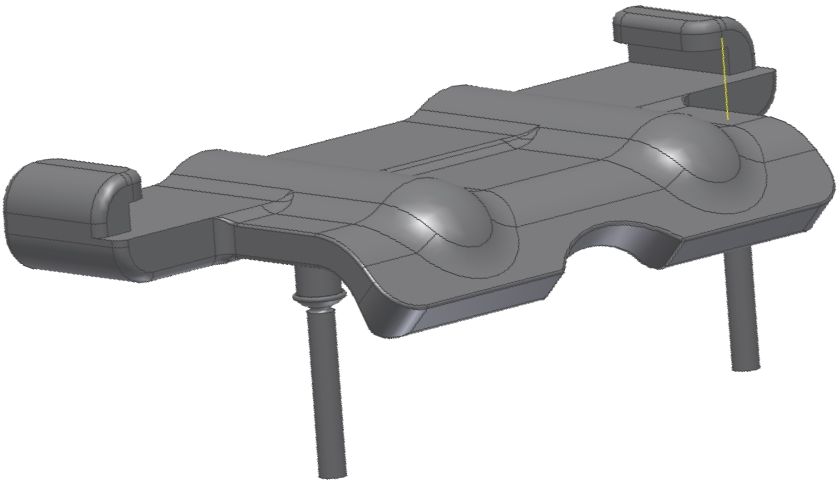

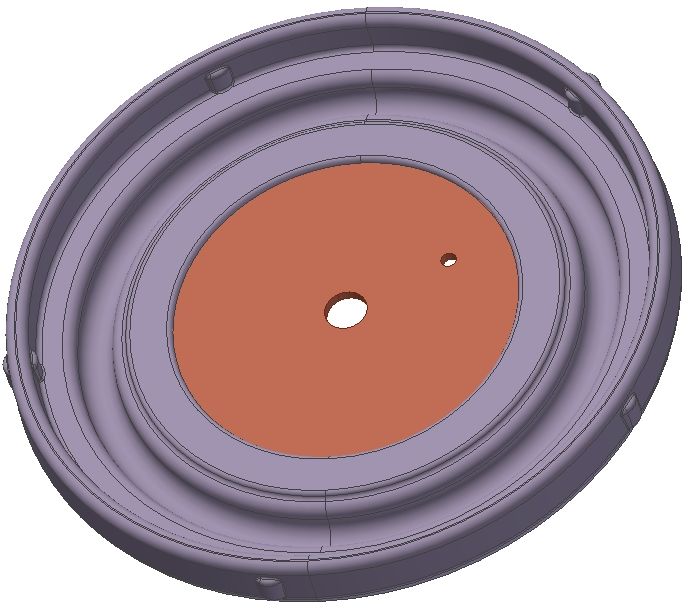

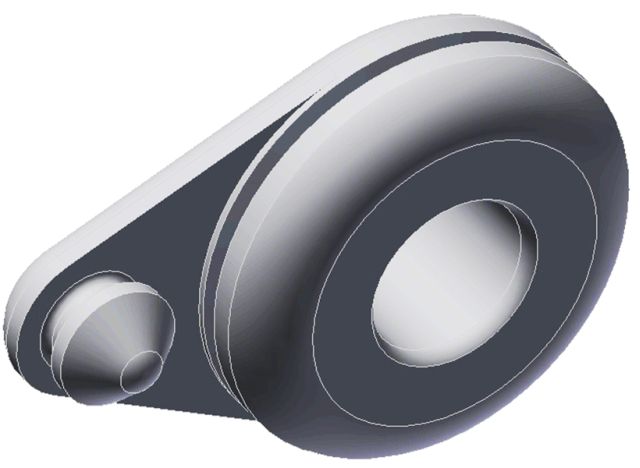

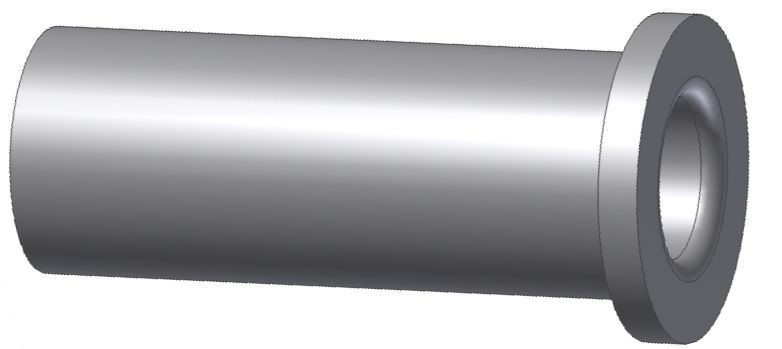

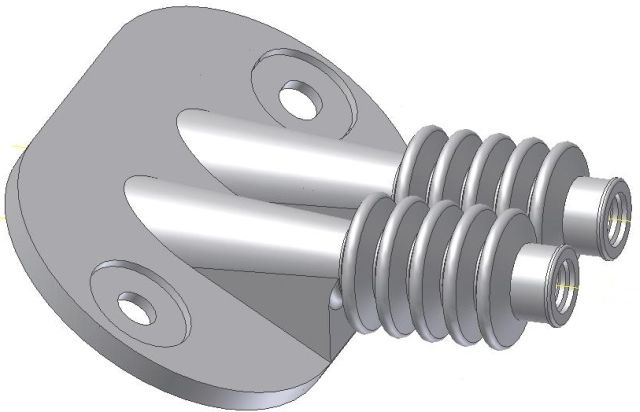

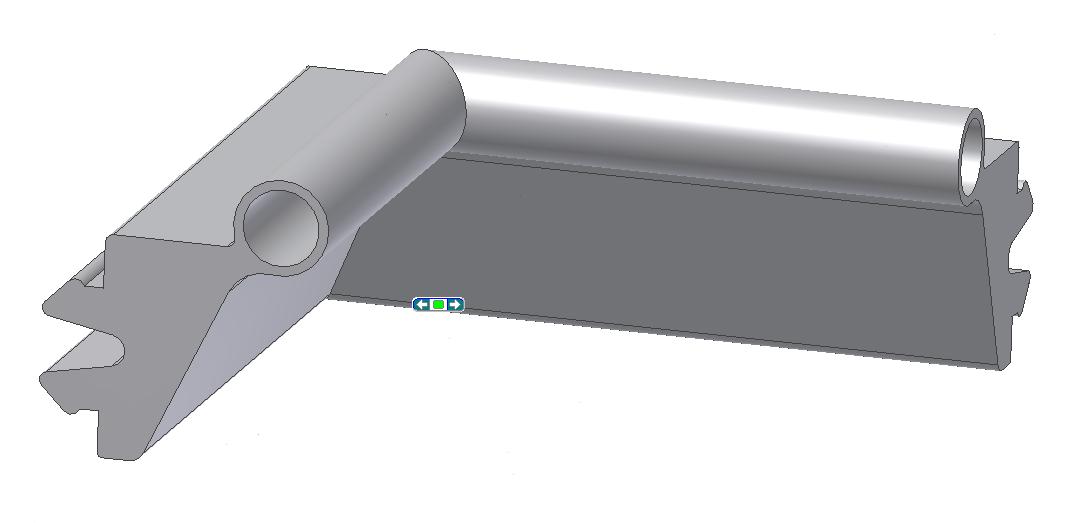

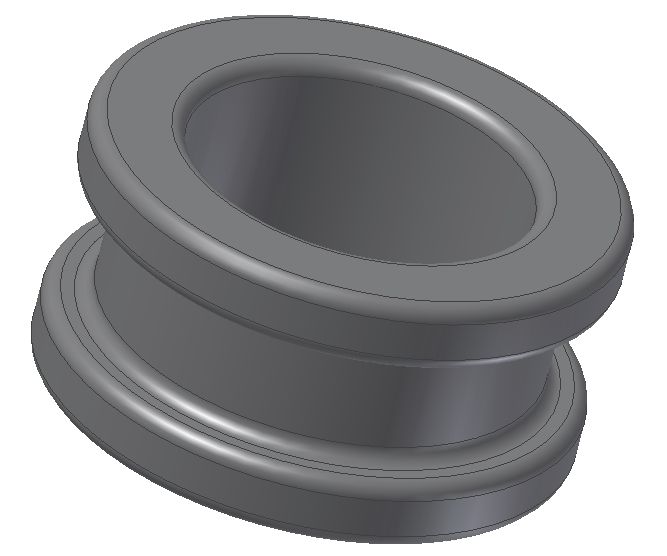

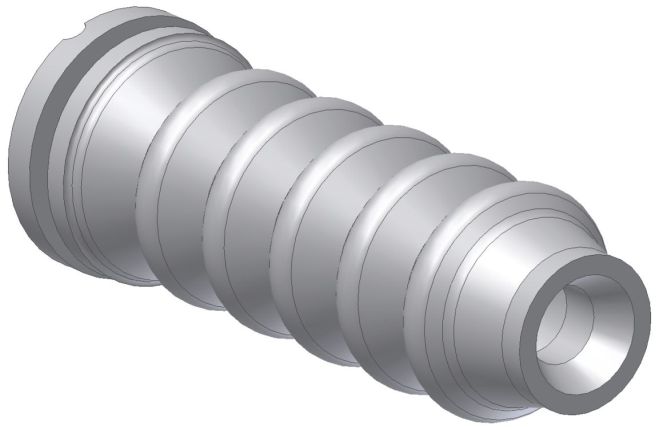

These components are used in vehicles to protect and isolate cabling and tubing where such components pass through other components. Their primary purpose is to prevent any possible damage caused by the sharp edges of other components or materials. These components are primarily produced using an EMDM mixture.

.jpg)

Their diverse range of applications is clear given their distinctive and individual designs. Components are produced to a high level of precision in order to precisely fit in the designed penetration and to ensure that the items passing through the bushing (wire harnesses, tubing, control cables, etc.) are properly sealed and that dirt or liquids cannot penetrate through.

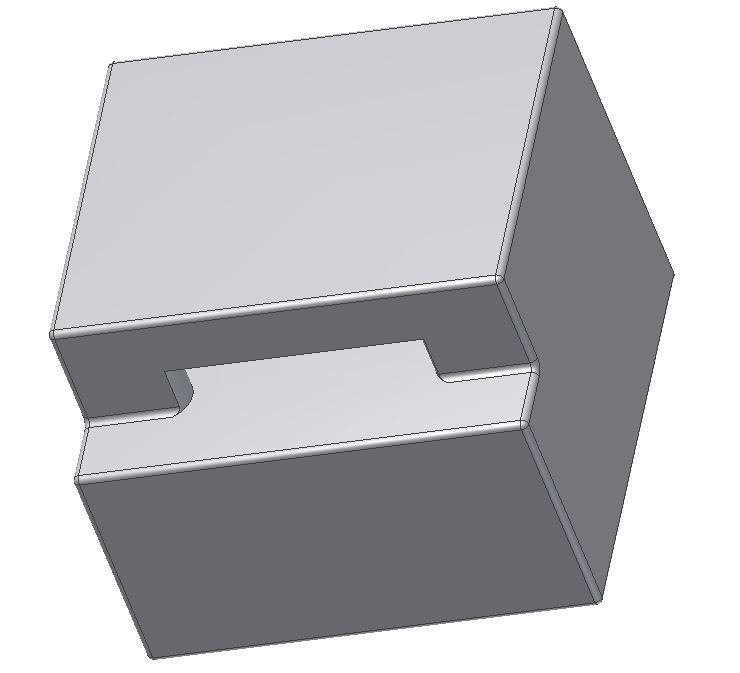

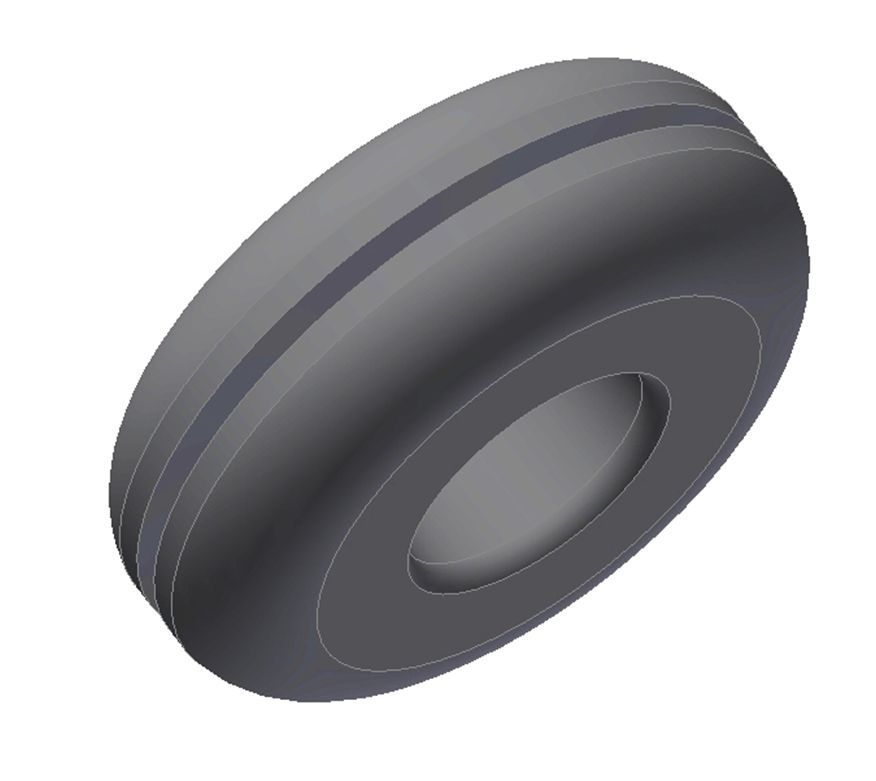

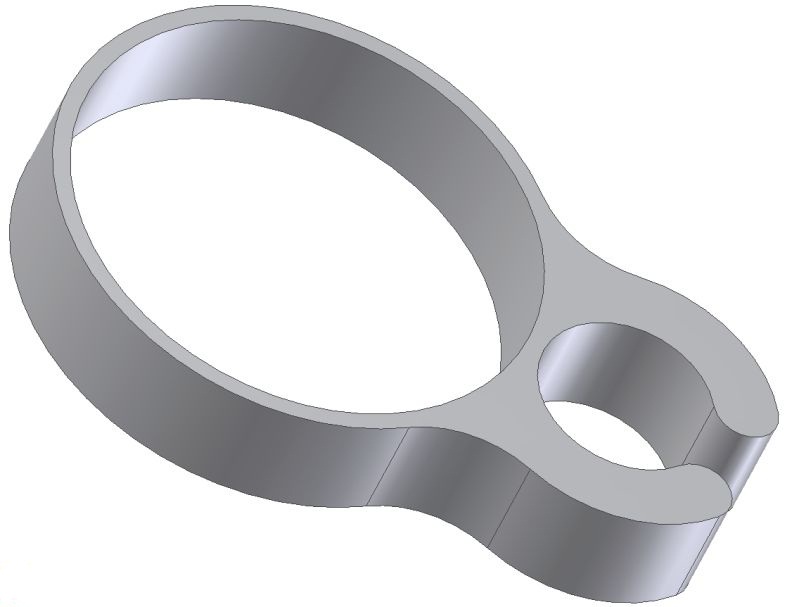

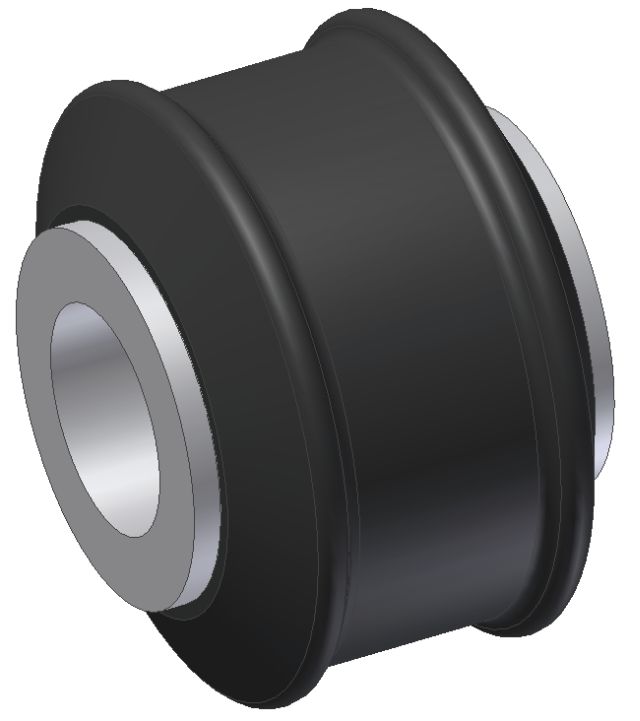

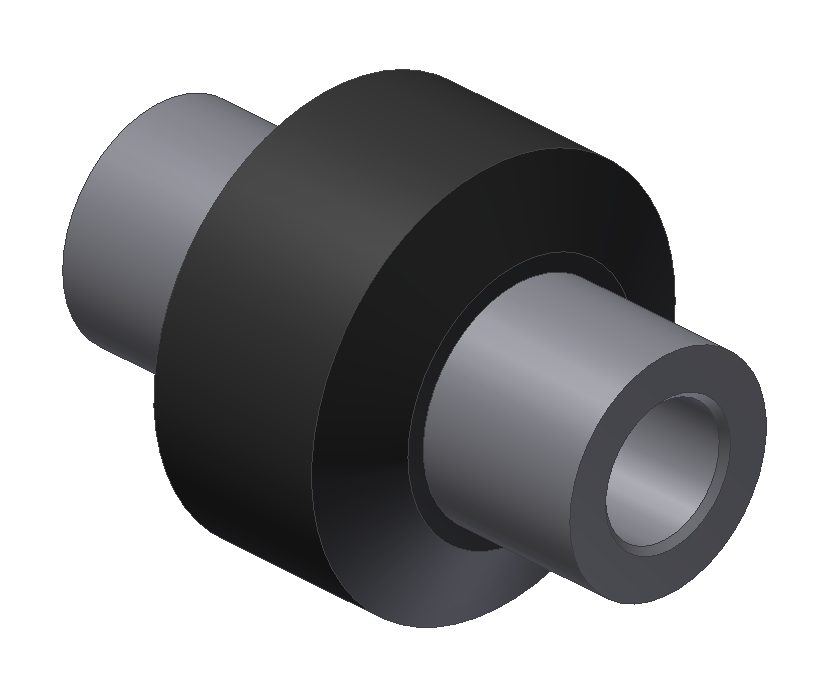

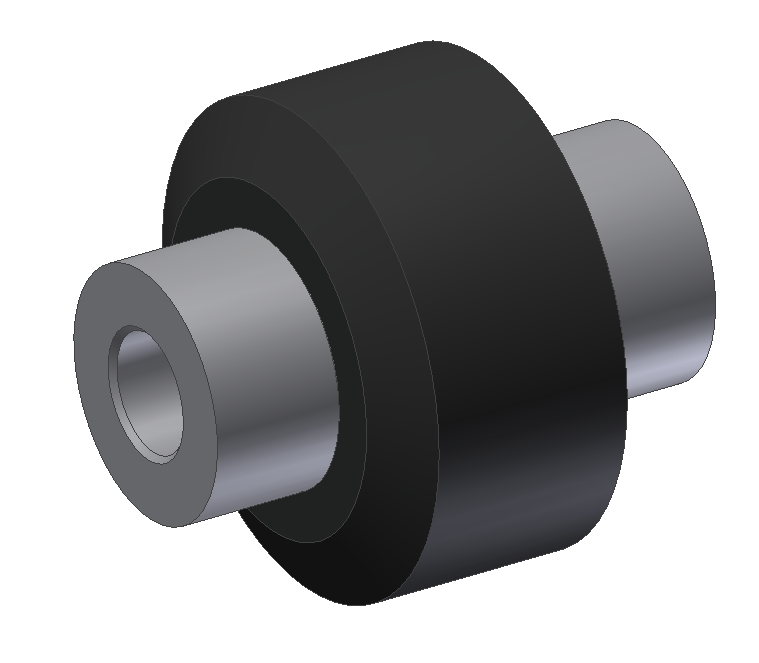

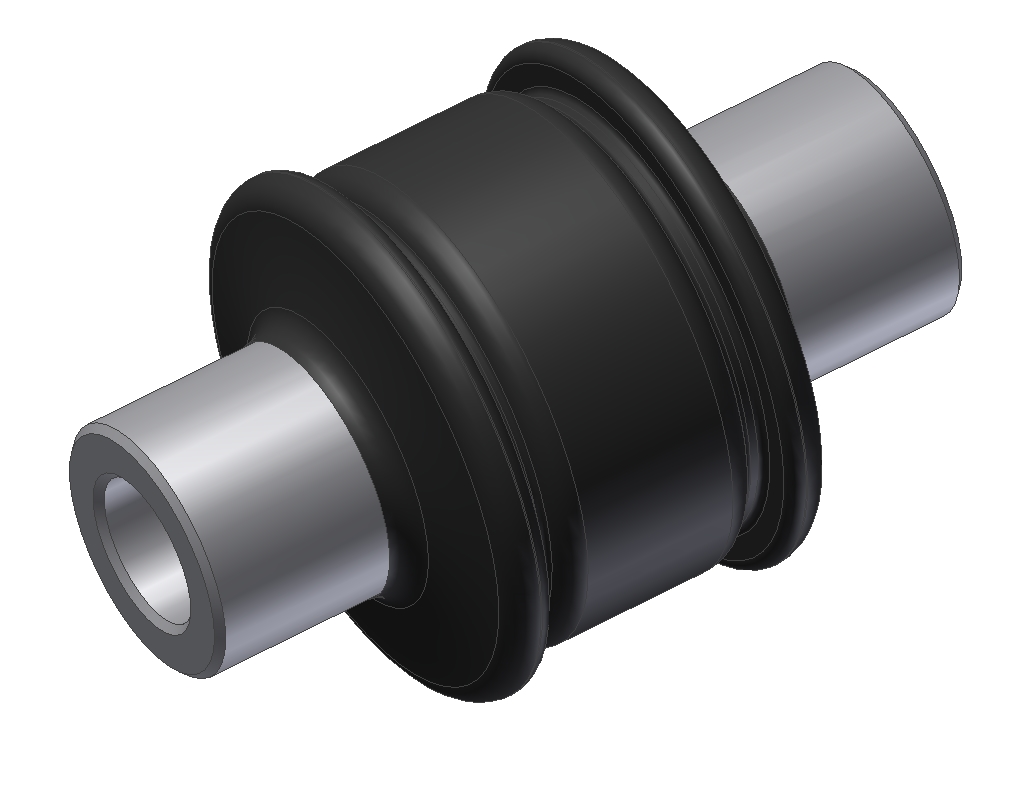

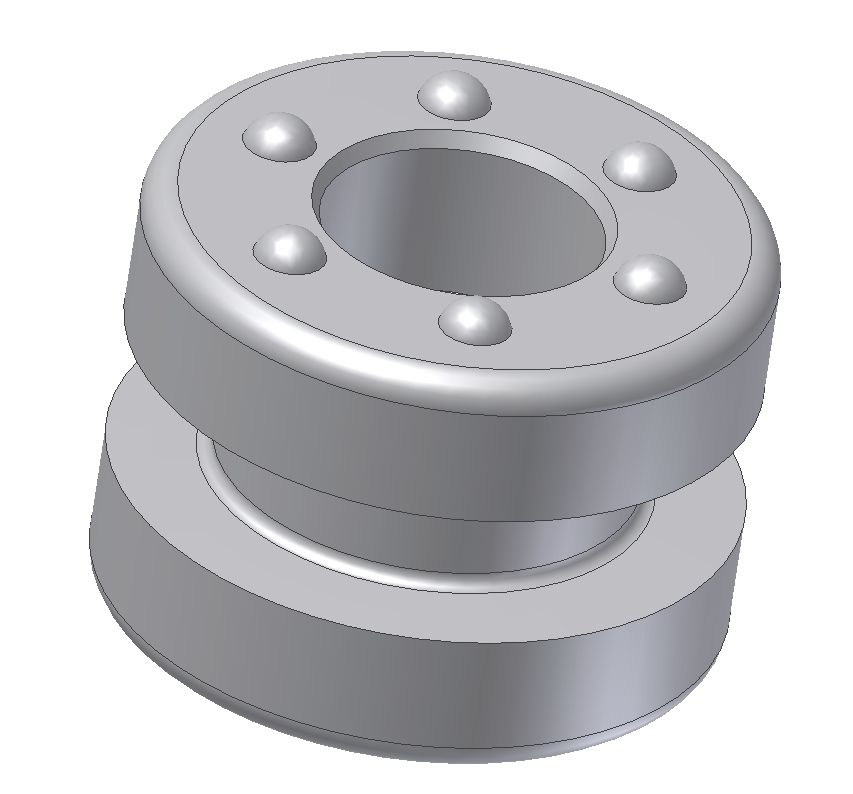

High demands are placed on these components in terms of their isolation properties as this is their basic function (to isolate components from impact or vibration, etc.). NR mixtures that meet the specific requirements of the application are most commonly used for such components. These components are finished to varying degrees of hardness depending on the working loads of the finished products. A few models are provided as examples.

More are not shown simply because their appearances are so similar. The most common type combines a metal core on which vulcanized rubber is applied. These are most commonly applied on shock absorber, axle, motor and transmission mounts. The components have a high level of dimensional precision in order to properly operate without any deviations.

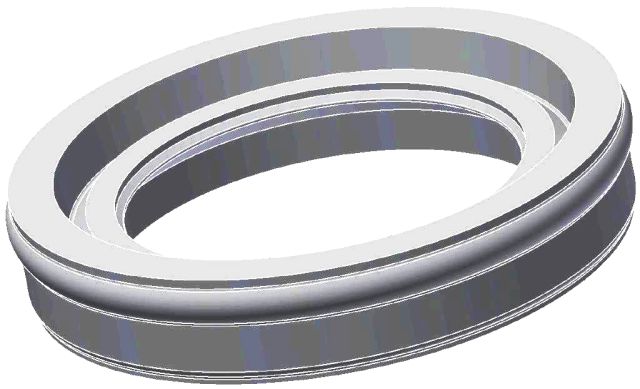

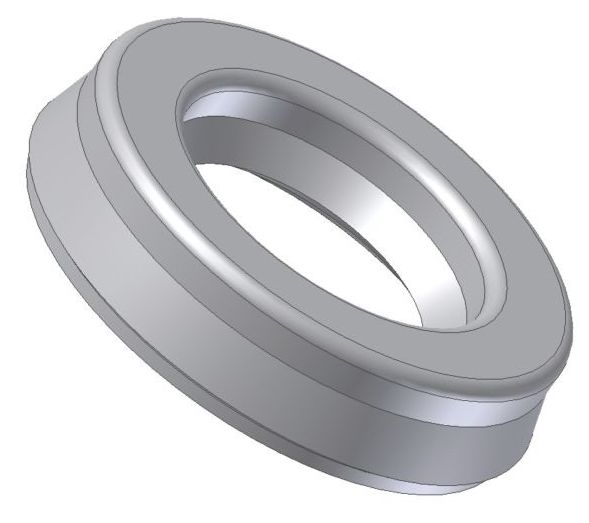

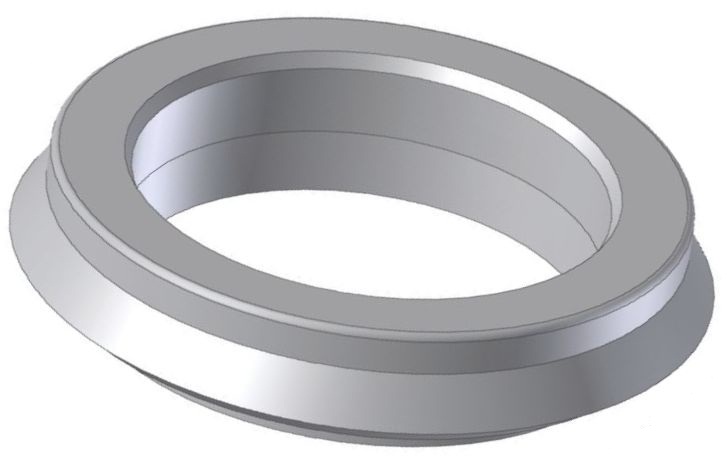

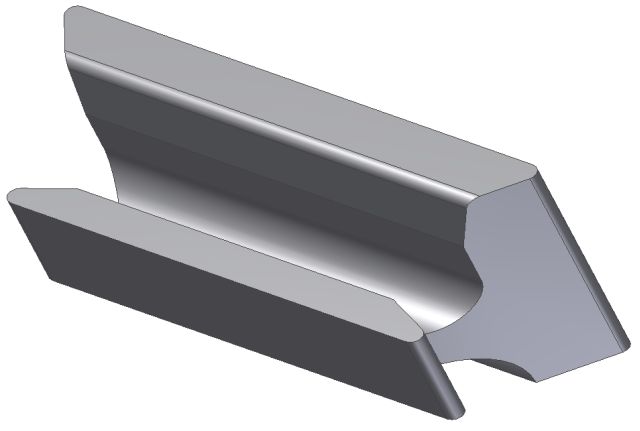

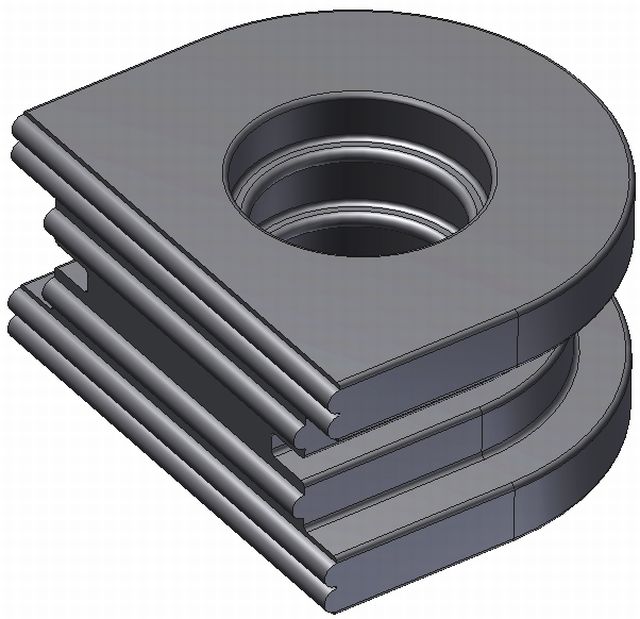

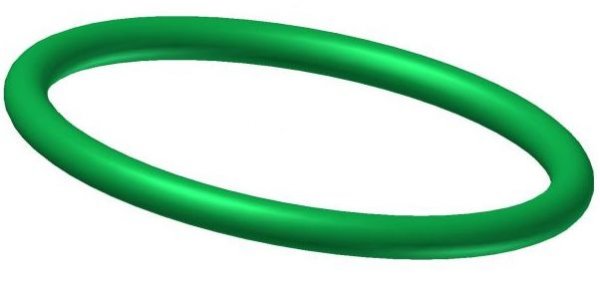

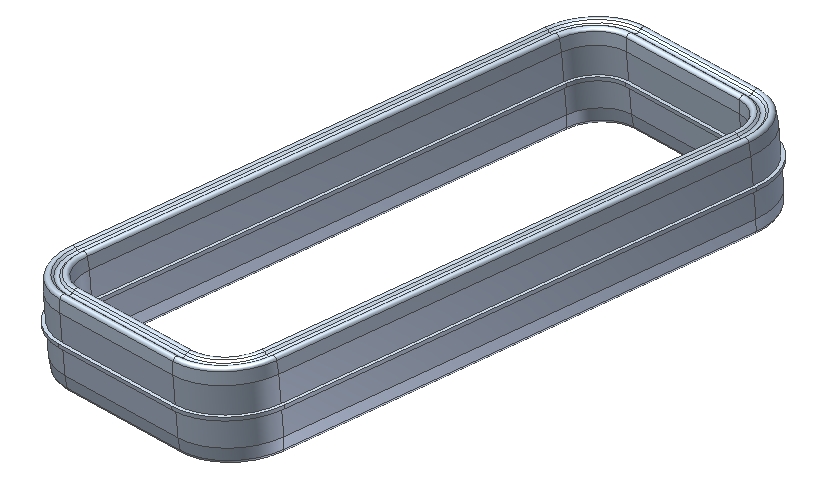

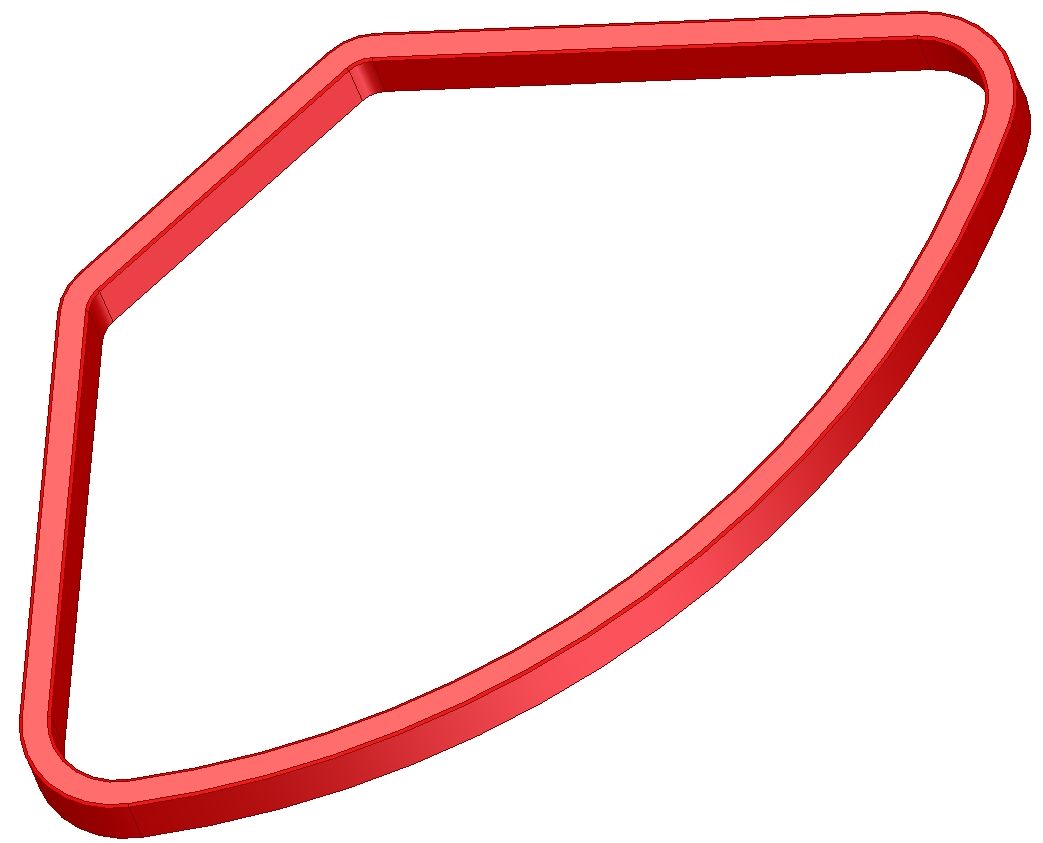

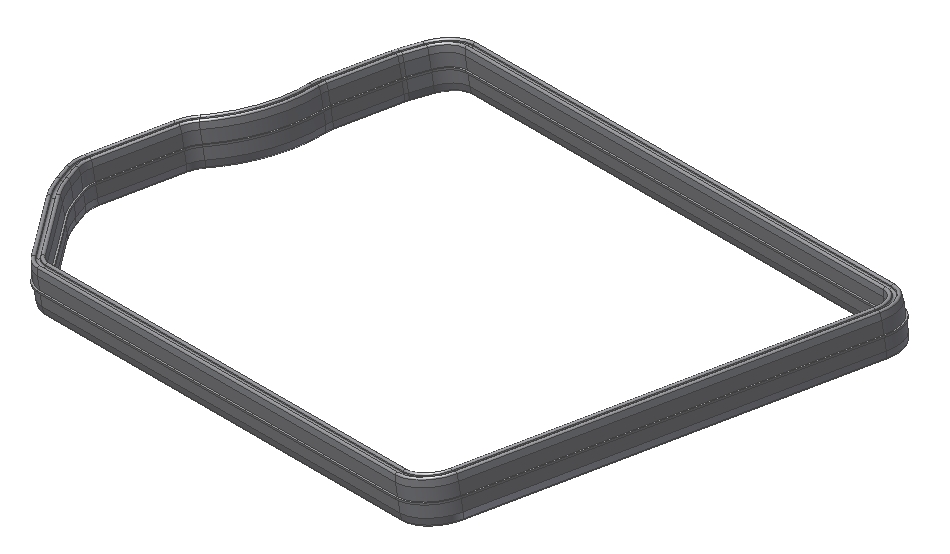

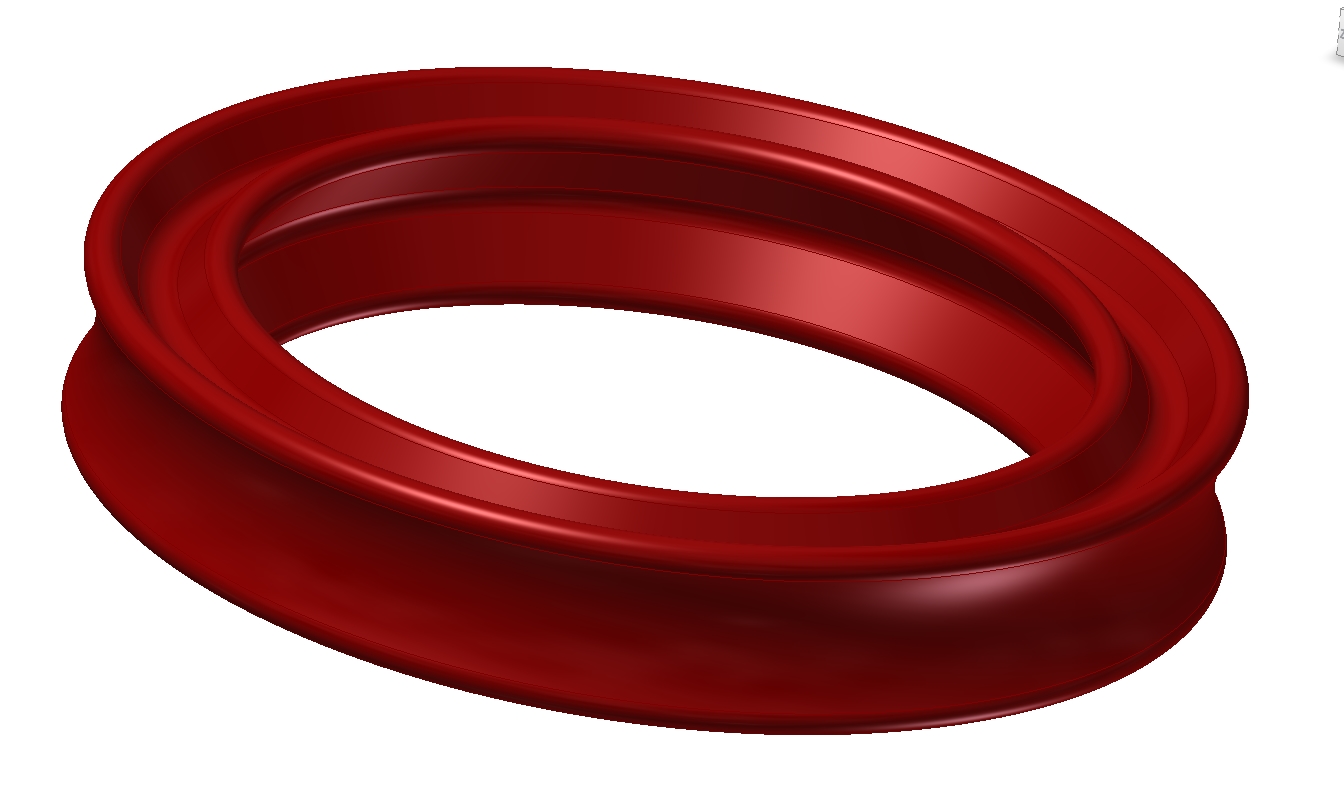

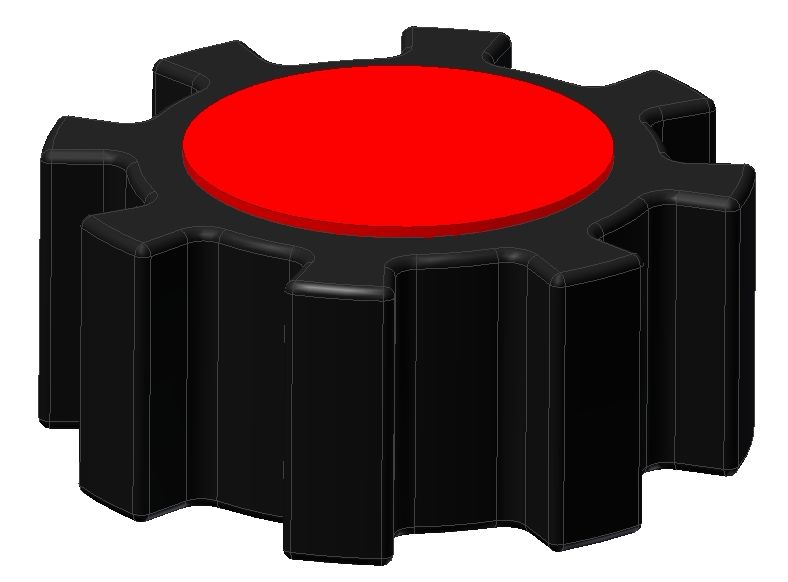

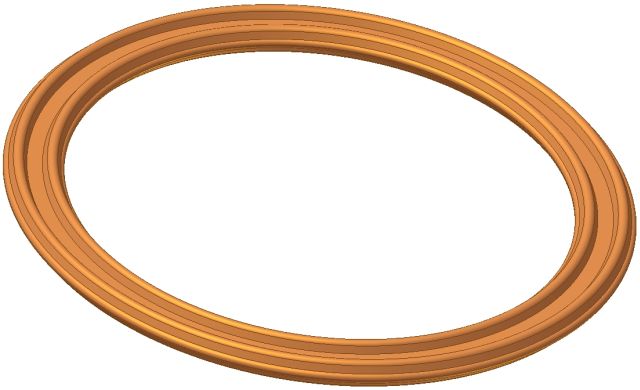

The seals we produce for our customers have a range of shapes and applications. The shape of each seal and the type of mixture used during production depends on the specific application of the seal. Seals are made from the following materials:

EPDM, NRB, FKM, ACM, VMQ, …

The previous images show that seals can be made from a single material, such as rubber, or may integrate other materials such as metal or plastic. One of the most important properties of any seal is high DVR strength as most of these components are subjected to mechanical loads.

Products with a high isolation function are known as shock absorbers. These products are primarily made from softer materials and the actual type of material is selected on the basis of customer requirements and primarily based on the environment in which the specific product will be used. Such products may be made from NR, EPDM, VMQ and other materials.

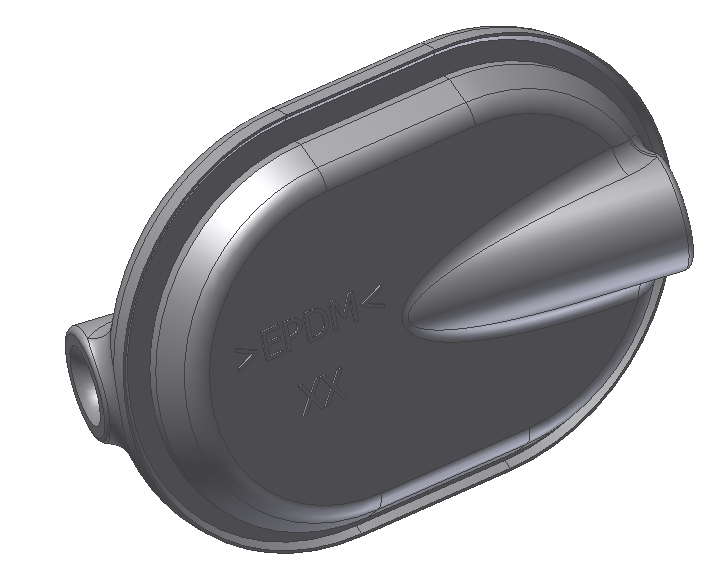

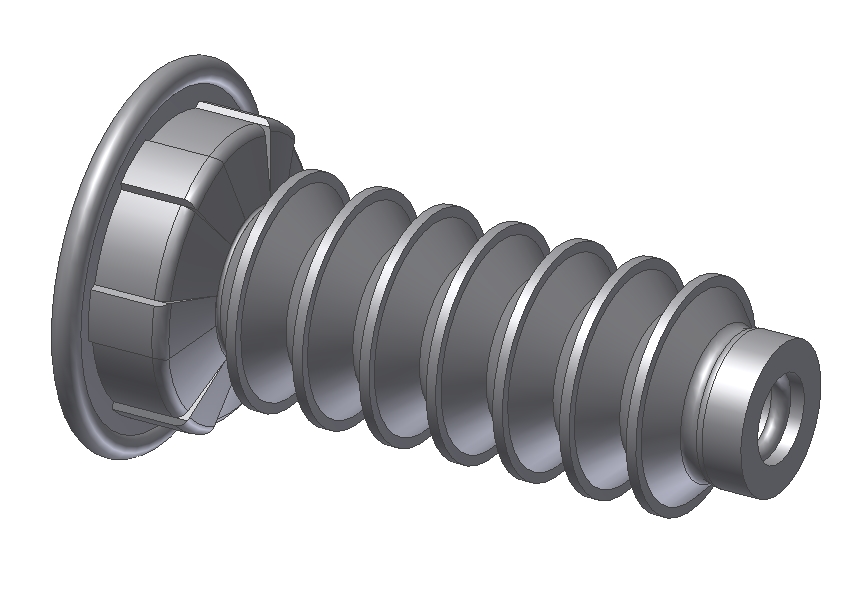

Dust boots are most commonly used as a cover to prevent contamination of a specific part from the outside. They are specific in terms of the need for flexibility in all directions and must be well matched to the activity or action taking place inside the protected area. These components may be produced from a range of materials depending on the work environment and the substances that the components may come into contact with. Examples include CR, EPDM, VMQ and others. They are used at the ends of control cables, various linkages, etc.

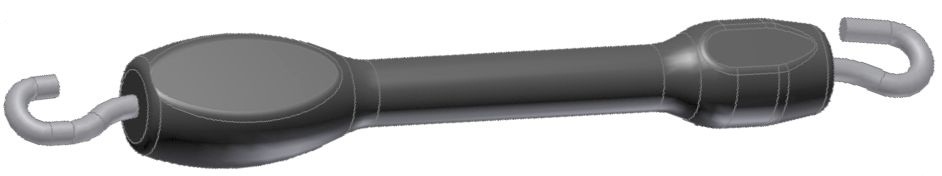

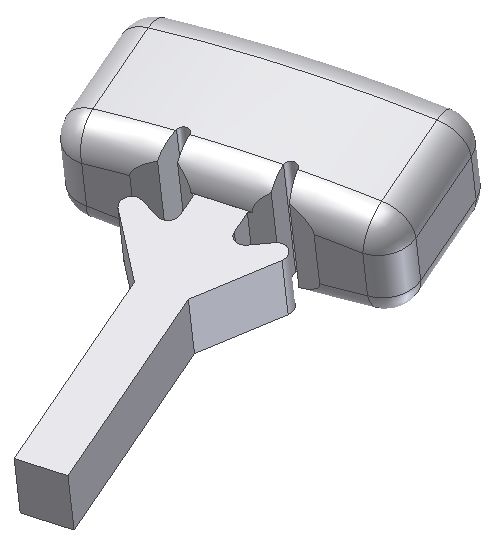

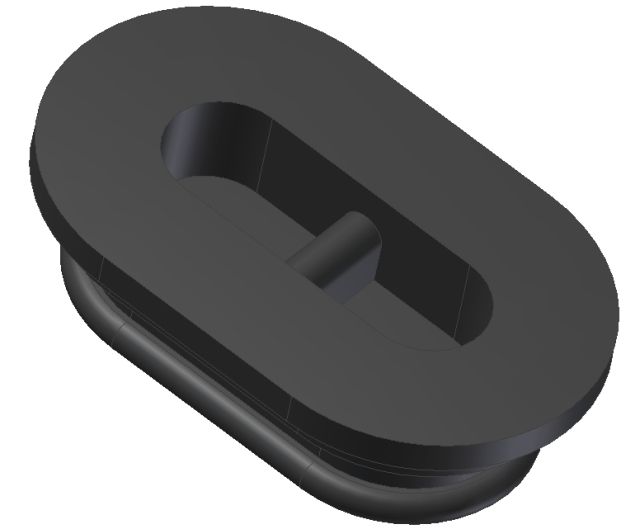

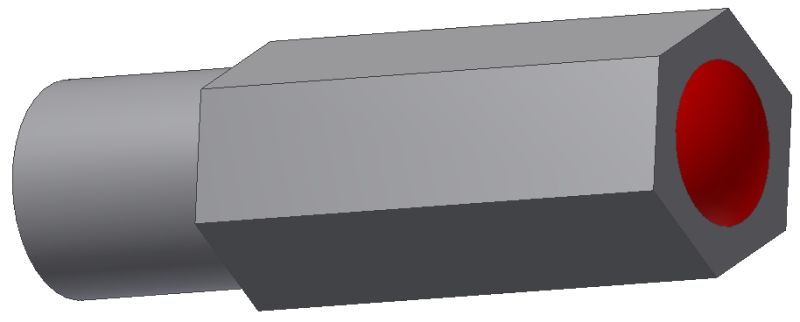

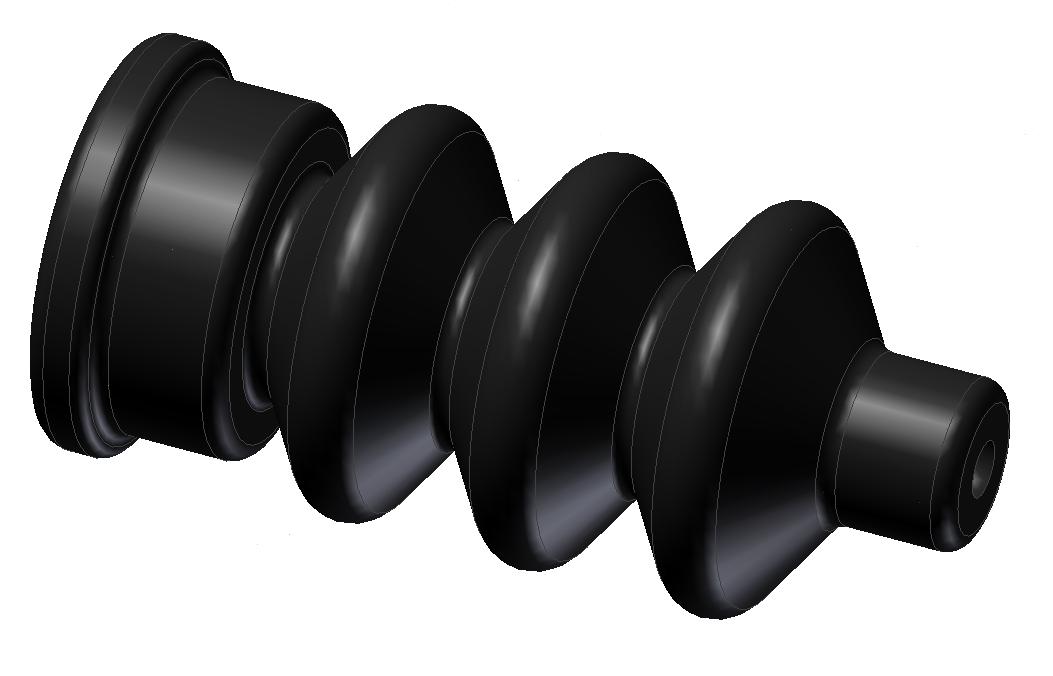

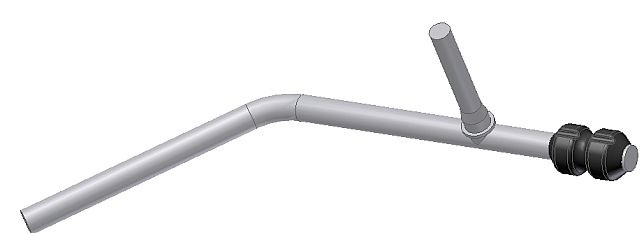

Shift linkages on which we vulcanize rubber are used in transmissions gear levers where the rubber on the surface acts as a silent block to limit the transmission of vibration from the transmission to the shifter. The rubber moulded to the surface of the metal rod can achieve various levels of hardness, the most common is around 35 - 50 ShA, but depends on specific customer specifications. NR is the most commonly used material.

These linkages come in different lengths but their basic shapes are similar as is clear from the images.

We also produce other products that are not categorized. These include dampers, connectors, filters and more ... .